Principles of Robotics Final Project

As the second class in the robotics concentration lineup, Principles of Robotics required a higher and more advanced level of work towards a fully formed robot for the final project of the class. While the description was simply to either add a novel concept to an existing robot or build a robot with a specific purpose in mind from scratch, the execution was intended to be more complicated. This was compounded by the fact that this class was taught on a hybrid schedule of 75% remote and 25% in person.

As I had in the previous class, I chose to develop my own robot in order to improve my skills in full robot development rather than simply in integration.

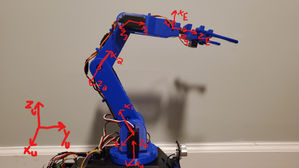

Omni-directional mobile robot with arm and trailer (nickname Towby)

All mechanical parts of Towby were designed in SolidWorks and either 3D printed in PLA, or laser cut from acrylic. This includes the trailer, the arm, the acrylic base, and several mounting parts for the electronics. All of this was performed using personal SolidWorks licensing and a personal 3D printer.

Limitations caused by finances, supply chain issues, and access required design changes throughou the robot. Namely this can be seen in the navigation and object identification system. Originally, the system was designed to utilize a vision based system of OpenCV integrated on a PixyCam camera. This was adapted to an array of ultrasonic sensors placed at key locations around the robot in order to maximize object detection. In order to improve object and wall detection, IR distance trigger sensors were incorporated for added robustness.

With the incorporation of the arm, many things needed to be calculated in order for it to function. Utilizing inverse kinematics by method of DH tables, the position of the arm was calculatable by the calculations for the position of each joint. Full operation of the arm, excluding the twisting base, was achieved and accuracy of the arm to the goal point from the achieved point was within less than an inch of difference.

Full operation was successful but limited due to last minute complications and part breakages. The omni-directional drive encountered issues with a faulty motor driver part preventing full omni-directional movement but still allowed for differential drive steering. Code incompatibilities and processing power limited trailer maneuvering algorithms making hopes of backing the trailer up a future dream.

While this version of Towby is not perfect, plans are currently being developed to improve and redesign Towby to iron out and remove flaws from the first version and improve functionality in the future. This includes an arm redesign, so size and strength match the chassis of the robot, improved motion systems, and faster/simpler algorithms to operate motion, trailer maneuvering, and arm kinematics. Hopes also include implementing control theory on the chassis in order to perform autonomous path planning, OpenCV on a camera for object detection, and trajectory planning for the arm in order to improve movement.